|

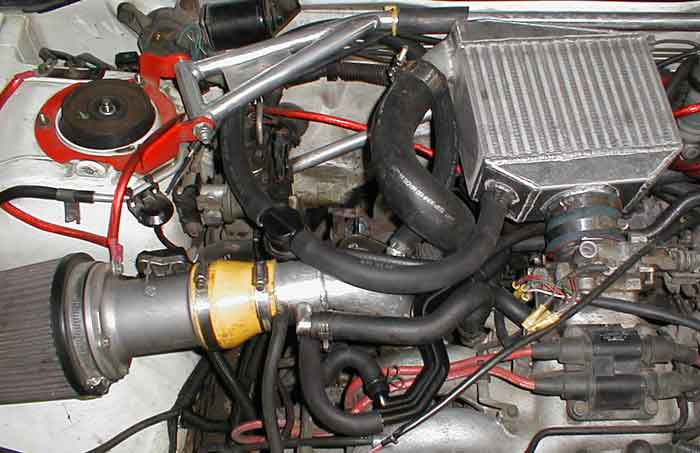

Air - Air Top-Mount Intercooler By Dave Ok, i'll admit it. My prior attempts to intercool have been half-hearted at best, but i think i was going into them a bit optimistically with regards to the ease of the project. Well, two intercoolers later, i still wasn't any closer to my goal. So, i waited, and waited, and then one day an intercooler popped up on eBay. It was a bit pricey, and the description didn't give me much hope, but i looked. What i saw was a customized IC made around a Spearco core, meant to go on a 2.5RS Turbo. This intercooler had indeed served in such a capacity before its owner decided that more was necessary in order to run faster. I asked the seller about dimensions, then measured. They seemed to be really close, my only concern was for the clearance from the throttle body to the firewall. I paid up and here's what i got. It was actually 3.5" thick instead of 3" as i was quoted, but it still fits pretty well considering. The factory ones are at least 3.5" thick, perhaps more. Here are some more dimensions: Left to right, including inlet: 12" Now i had to install it, and that would be much less traumatic than it had been in the past, partially due to the size of the unit itself, and partially due to luck. I took the stuff i had to a local shop who's had a reputation for putting custom turbo kits on Hondas, and which had some some very good work for three friends. We had to make a few decisions about where to route stuff. The IAC was kind of in the way and the BOV routing was looking to be messy. We decided to use the IAC hose to run the BOV through the port in the intake that the IAC was using, and run the IAC through the port the BOV was using previously. It was a little kludgy, but it worked. The big problem seemed to be how to get the turbo outlet to the IC inlet. Shane was prepared to fabricate something, but while pondering as much, he happened upon a lower radiator hose that looked really promising. It turns out that this hose was about a 98% fit, with just a little trimming and bending needed to get it to fit right. A few days later i decided that the BOV and IAC routing wasn't sufficient, so i returned the IAC setup to its previous location and debated on how to get both the BOV and heretofore disconnected PCV system hooked up. Using some creative plumbing and some of the old parts i'd taken off the stock intake, i got everything connected up nicely. So, was it worth the effort? I'm certain it was from the moment i first drove it. It pulls hard now, as the air is that much denser and cooler than before. After a drive, there is a substantial difference in temperature from the upper to lower endtanks, so it's plainly evident that it is indeed doing the job well. Installed Images:

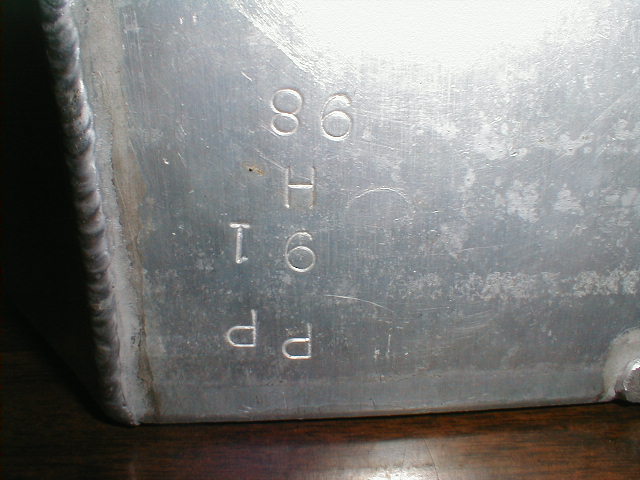

Pre-installation images:

|